Holy cow, what a week! Made it back home after putting over 1000 miles on the Jeep. As a recap, my wife drove it 500 miles to Painsdale, MI where we celebrated mother's day with my In-laws and I did double duty working on the old family farm in the evenings and worked from home in the morning. Wednesday, I worked a half day, then left from Painsdale to drive to Drummond Island (just over 300 miles). Had the dog, a suitcase, and a box full of spare parts and tools. That was a long day. Spent Thusday, Friday, and Saturday wheelin all day long. Finally drove home today, got an early start and hit the 8:10 ferry off the island. Another 300 miles and 5.5 hours in the jeep. I'm whipped. Lots of time in a small vehicle. Plus, I think I lost another weight or a tire spun on the rim. I didn't have a perfect balance to start, but it was worse on the way home. That constant shake is fatiguing. I've had such an issue getting these tires to balance, I think its time to sell them to someone less picky. I'm kinda leaning toward some Baja Boss A/Ts. Going to start watching the sales.

We had four rigs, an XJ on 35's, another TJ on 33's, and an LJ on 35's. We swapped out vehicles a bit more this trip and I rode in a TJ and LJ a bit (I've been a passenger in the XJ a lot). I can really see the difference in builds going back to back like I did. Not so much in capability, but more about smoothness and ease of the driving expereince. My jeep is a FAR nicer place to be wheeling in than the others in the group. Enough so that the Wife of the owner of the LJ asked him how come his jeep didn't ride like mine? That was a fun discussion.

Both the other wranglers have bedlined interiors and the resonance of the tub is drastically different than mine too. It was like sports arena to library difference in overall noise. Things like where the exhaust exits, how tools are carried, etc, is all important to your fatigue level at the end of the day. Lastly, both Wranglers were manuals. The amount of work that goes into wheeling a manual in technical sections is crazy. I knew it, but after a couple years with the auto and having done a lot of the same trails with both now, I will never build a manual jeep again. My Jeep is getting to be a point and shoot machine (In Michigan, anyway) and its very satisfing to have built it myself with help from my forum friends. This trip also makes me want to get my Foxes installed but I need a new frame first.

Overall the Jeep performed very well. My transmission leak was solved with the extra clamp, so I'll have to rebuid those lines. It needs to be done anyway, since I want to install an oil thermostat in the system. I wheeled pretty hard for three days and only saw the transmission temp tick up to 160. Never got any hotter. I think I'm going to run the oil through the radiator first, then let the thermostat decide when to start flowing through my aux cooler. Right now, its plumbed aux cooler, then radiator.

I had to pull cable once, when my tires just wouldn't grab and the front and back were trying to climb at the same time. I was climbing a cliff face and didn't really have enough room to reposition, the face was at an angle that kept pushing my rear pass tire toward a drop off, so I swallowed my pride and tied off. Climbed right up then. I had one other climb that I just couldn't get traction on, but I was able to reposition and get up without assistance. General Grabbers just don't seem to be a good rock tire...but maybe it was just the spot. The LJ struggled in the same place and he is running MT/R's.

I'll post some more trip recap stuff in another thread over in the regional forum (including some carnage!), but for the build thread, here are a couple pics...

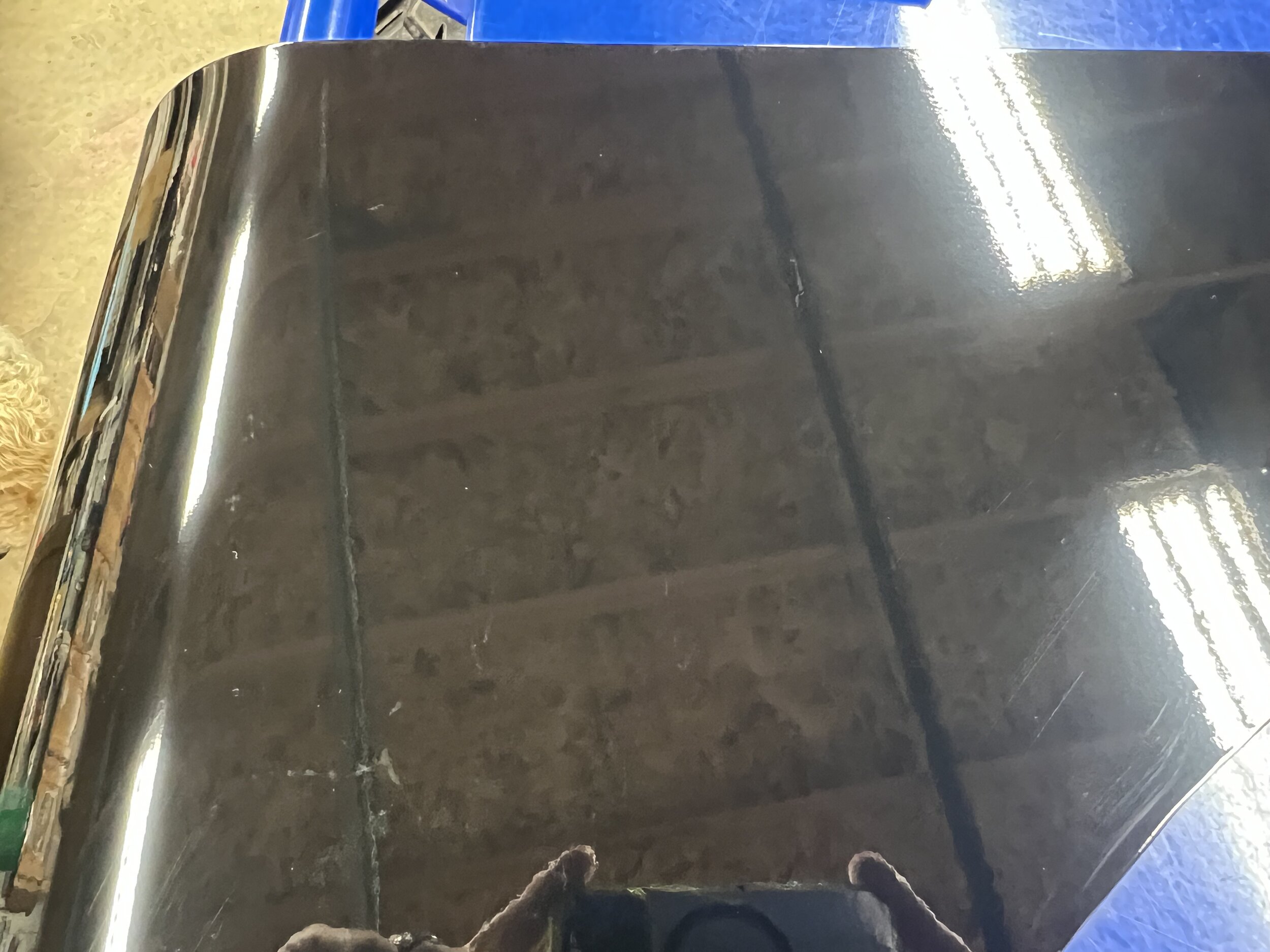

Need to do some cleaning...

This is a feature called Connor's Hole Its about 300 yards long and the water was up to my sliders/floorboard. Nice rocky bottom though, so as features go, its pretty easy, just required a bit of a steel spine to actually drive into that water.

This was my wheelin buddy for the week. She was pretty anxious at first, but she started to get used to it after a couple days. She still doesn't like the really bumpy, rocky stuff, but at least she doesn't pant and drool down dirt roads anymore!

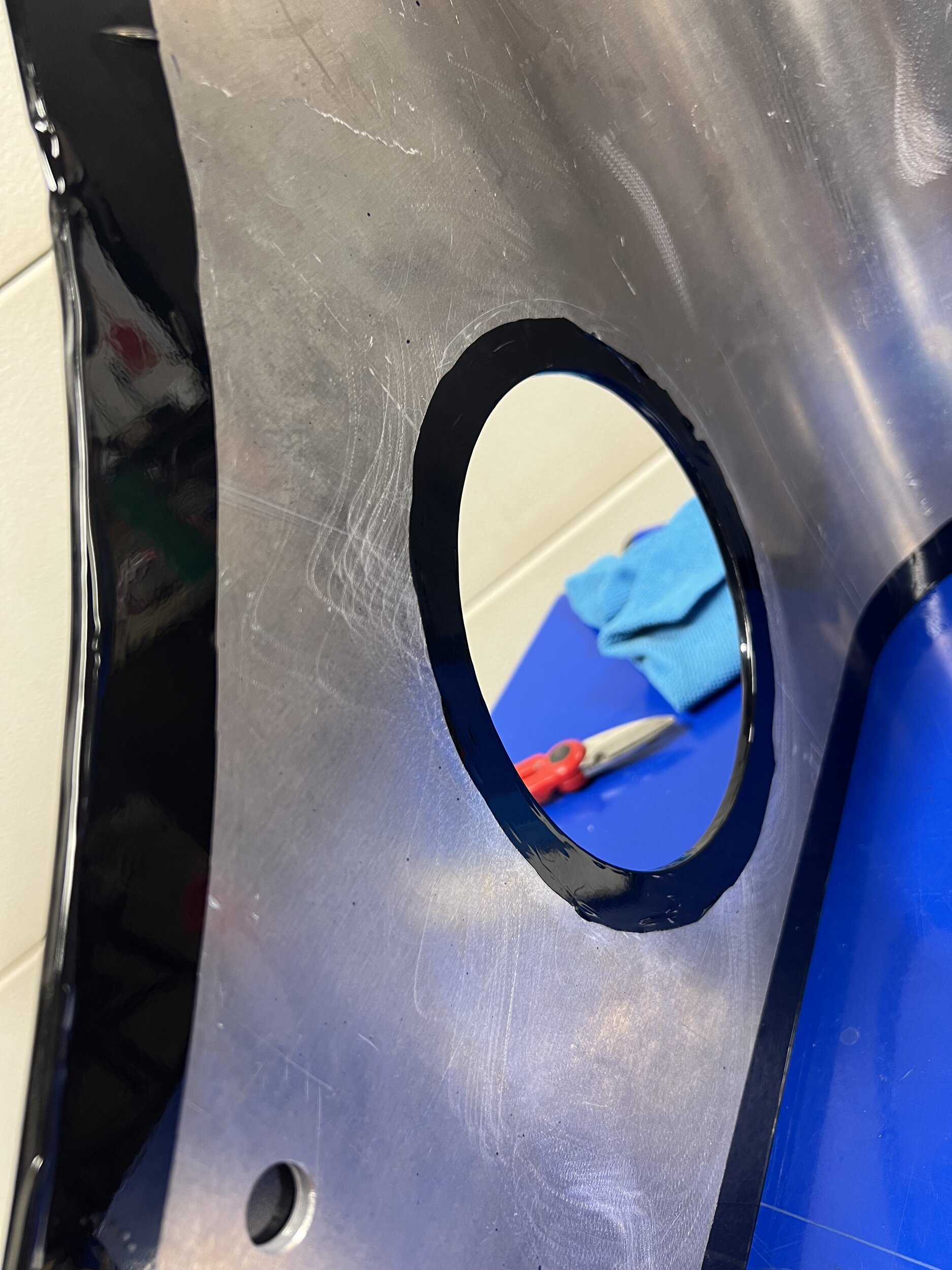

And I saw a big stump, so obviously, I needed to "check for clearance issues" on it. Note: That is actually where I found the pulled locker sensor wires, LOL!