Today, I actually started on the to do list for this build with #1 - fixing the broken fuel filler nipple on the fuel tank. It was likely broken when I installed the body lift. This repair is no longer

required because Mr. Blaine sold me a good used tank at a very fair price (see

Post #43). However, I wanted to see if repair was feasible, and if so, I'll have a good spare tank. I started by researching plastic welding.

Oddly enough, my plastic welding journey began about 34 years ago. I had just quit grad school to pursue a career in motorcycle racing (as an engineer, not a rider), and I was hanging out at the race track with club racers and riding sport bikes on the street. The bodywork on the race bikes was fiberglass, and repairing fiberglass was pretty straightforward; however, repairing the OEM ABS plastic bodywork was a new process. Back then, plastic welders used heated nitrogen or compressed air, and they were very expensive for a just-graduated engineer. I did some research on the machines and the process, but I couldn't afford the machines, so none of that research evolved into practical application.

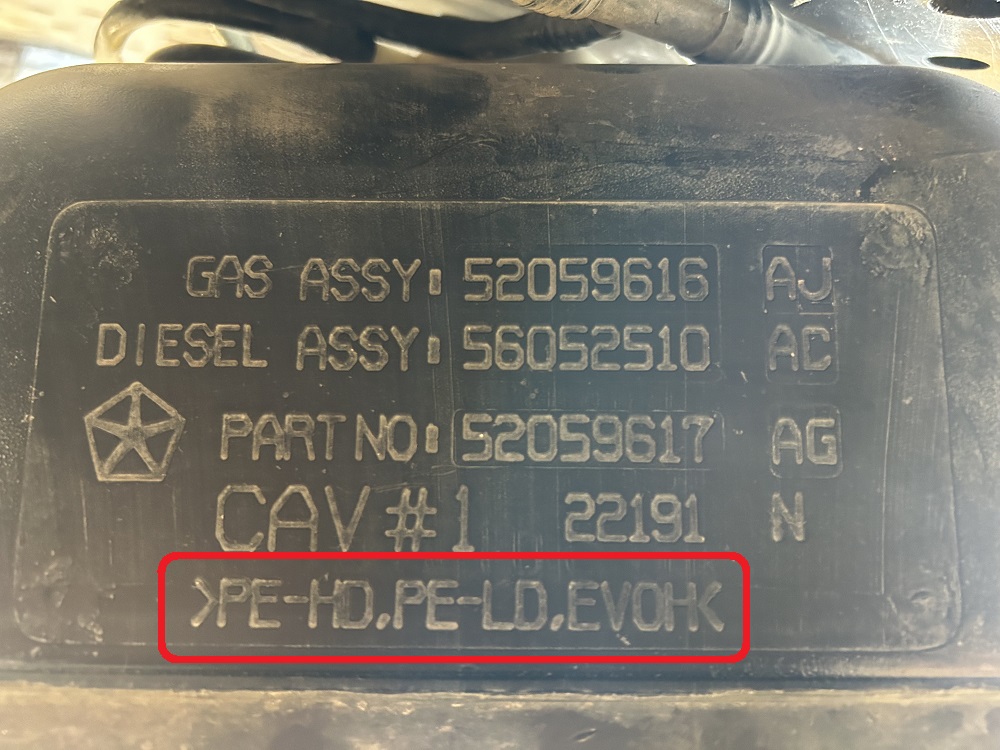

My new journey started with researching how the process and equipment has changed in the 34 years since. I started with determining what kind of plastic the filler nipple is made from. I know from my previous work that plastic fuel tanks typically have the plastic types noted on the tank via mold notes, so I found that note on my tank:

The "PE-HD" is high-density polyethylene, the "PE-LD" is low-density polyethylene, and the EVOH is an ethylene vinyl alcohol copolymer. Oddly, the normal acronyms for the two polyethylenes is LDPE and HDPE. I don't know why Chrysler used the other acronyms. The tank body itself is actually a multi-layer design. Both of the polyethylenes are not impervious to gasoline vapors (the vapors can seep through it), so the EVOH is used in the middle in order to pass EPA tests. The filler nipple is welded to the tank body, and it is a single layer, molded part. It's made from one of the two polyethylenes, but I was not able to determine which one. Fortunately, both can be welded with LDPE filler.

After determining what kind of plastic I needed to weld, I started new research on plastic welding technology. I discovered that the heated gas systems are still very expensive, but glorified soldering iron technology (now called "airless plastic welding") has progressed and seemed a lower cost possibility. I ended up purchasing a

MiniWeld Model 7 Airless Plastic Welding Kit made by Polyvance:

The kit contains the iron with temp controller, a stand, a cleaning brush, a bunch of different filler materials, and some stainless steel screen material to use for reinforcement. I decided to practice first. I knew that the every day five-gallon bucket is made from HDPE, so I punched a couple holes in one and proceeded to repair it. I didn't take many photos of the process. I tried the tip that has a feed hole in it for the filler rod, but I found that to be cumbersome, so I just used the spade-shaped tip shown above and melted the filler directly on/into it. It turned out well (not pretty, though), and it doesn't leak water:

This is the filler used (LDPE - HDPE filler is not available):

With the testing complete, I decided to tackle the tank nipple repair. Here's the problem:

After using a rotary tool with a brush to clean things up, I cut and formed a piece of the stainless steel screen material to use to reinforce the repair:

The idea is to use the iron to melt the screen into the existing plastic and then cover it with melted filler material. To hold it in place while melting it in, I used a needle-nosed locking pliers:

Unfortunately, I don't have any pictures of the actual welding process because I only have two hands, and I don't have a tripod, so I'll just describe it. The iron has convenient material settings on the dial, so I set it to "PE", for polyethylene, and used the tip to melt the plastic through the screen to imbed the screen into the existing plastic. I immediately melted a layer of filler material over that, and then repeated multiple times to build up a radius like so:

I'm actually surprised how sturdy it feels! When I load it by hand in the upward direction (the same load direction that broke it), I can see the part of the black tank outside the welded ring deflecting instead of the nipple. I think I have a decent spare tank!

The final step in the process was to smoke test the tank to make sure it wouldn't leak through the repair area, and it passed with flying colors. Here's a picture from the smoke testing:

Overall, it was a successful day. Tomorrow, I'm going to wash the LJ and put a cover on it. It lives in the shop, and my shop activities generate a LOT of dust, so I bought a cover for it while I'm working on it because the paint is in pretty good condition (not to mention the half doors, GR corners, and hood cowl have new-ish paint on them). After that, I'm going to tackle to-do list item number 2 - attempt to reinforce the top of the radiator tank where the common crack failures occur. My LJ has 55,000 miles on it, and it's the original, 19-year-old radiator. I have a spare OEM radiator, but I'd like to get as much life out of the original one as possible. Instead of plastic welding, I'm going to try a two-part epoxy kit (made by Versachem). I don't know if it'll work, so stay tuned!