Found this article on Extreme Terrain's website and just wanted to share it with my fellow TJ owners. Hopefully it helps someone in the future!

What is Death Wobble?

Death wobble is a rapid oscillation from side to side in your steering components and results in your steering wheel moving very quickly from side to side. It has earned this name because it feels like your Wrangler is literally falling apart and that letting go of the steering wheel can lead to a very bad day. When this occurs it becomes extremely difficult to control your Wrangler and the only way to get it to stop is to slow down, sometimes it is necessary to come to a complete stop. Death wobble typically occurs at speeds above 45 mph and in most cases requires a trigger like hitting a bump or a pothole, but can also happen at speeds under 45 mph. One of the common myths about death wobble is that it doesn’t happen to stock Jeeps, only ones that have been lifted. This is not true, it is actually possible to have death wobble in ANY vehicle with a solid front axle, and however it is true that if you have recently done any suspension upgrades (Ex: Lift kits) you may be more likely to experience death wobble.

Unlike normal shimming or vibrations from unbalanced wheels, death wobble is a distinctly harsher oscillating force and is very difficult to control. If you’re faced with this unfortunate situation, here are some steps to look into and possible help solve the problem.

What Causes Wrangler to Death Wobble?

Death wobble is caused by loose or damaged steering components, however it can also be caused by incorrectly installing steering or suspension components. The first thing you should check is to make sure that nothing is bent or broken, look at all of your front suspension components and if you see anything that is damaged it is a good idea to replace it. Your front track bar, drag link, steering knuckles, ball joints, steering stabilizer, upper and lower control arms, and even bushings should be checked for damage or excessive wear. In addition to properly checking that all corresponding hardware is properly tighten to the correct torque specifications. Another important thing to check is your wheels, tires and alignment. While unbalanced tires and wheels being out of alignment won’t cause death wobble, it can help trigger or even amplify it, so it’s a good thing to check just in case.

What to do When Death Wobble Happens?

If you are driving along and death wobble happens, the safest thing to do is pull over. Don’t let go of the steering wheel but maintain a lightly grip, the sudden harsh steering wheel movements can cause damage to your fingers if you have a tight misplaced grip, try to stay in the lane while slowing down and don’t pull over until the wobble stops, in most situations if you slow down enough the wobble will stop, but other times coming to a complete stop is necessary. If you try to pull over while you are wobbling at a high speed it can be very dangerous and you could lose control, just try to slow down quickly and safely without aggressive braking or forceful/quick movements of the steering wheel.

How to Fix Wrangler Death Wobble?

One thing that many people do is simply install a new steering stabilizer, however this does not fix death wobble. Steering stabilizers in some situations can temporarily get rid of death wobble, therefore masking the serious problem. During the diagnosing of the issue, it sometimes help disconnecting the stabilizer in order to properly pin-point the problem. The best thing to do is inspect your steering components and find the part or parts that are damaged or worn out, most likely it will be the front track bar, tie-rod ends or the ball joints.

How do I Figure Out What Needs Fixed?

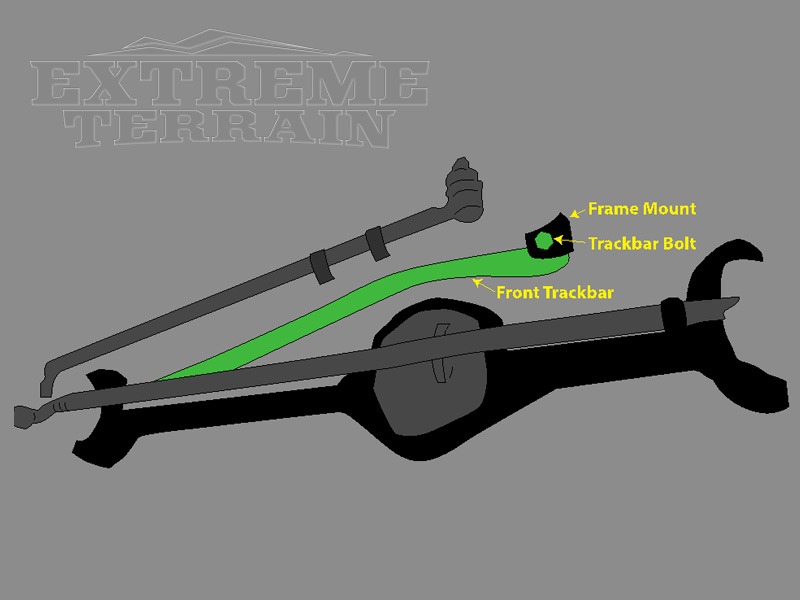

Track bar: The front Track Bar is designed to absorb a tremendous amount of force, as a result the two anchoring points are extremely critical and should be the first stop in your investigation of the problem.

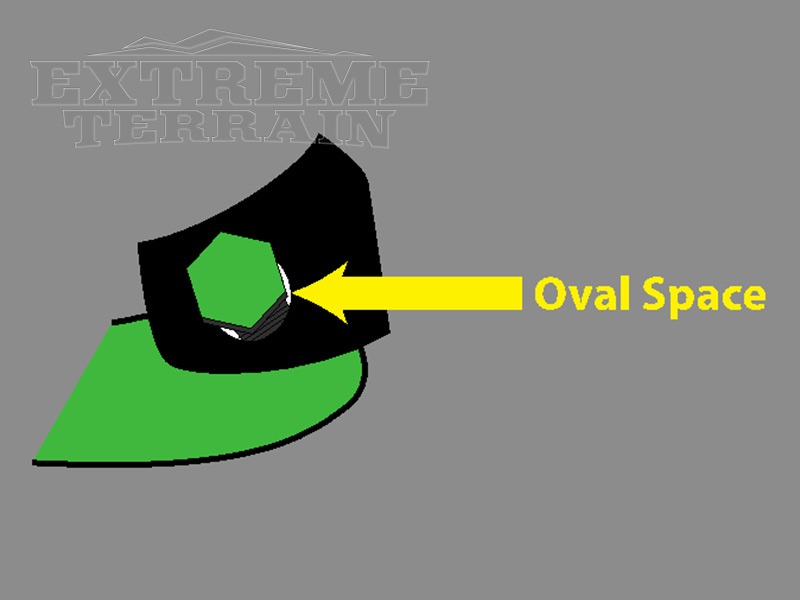

The “Frame Mount” bolt is especially known to be problematic. This high grade bolt requires 125 ft./lbs. of tightening torque. If loose, the bar’s force could oblong/enlarge the frame mount’s hole, causing the bar to have excessive play.

Another way to see if your track bar is worn out and needs replacement is to grab a buddy and check it out. Have your friend hop into the jeep and start it up, then have them put it in neutral with the parking brake on or if you drive an automatic, put it in park. Next lay down and look underneath your wrangler at the front axle, you should see a bar that connects the passenger side of your axle to the driver’s side of the frame and it will have a curve to part of it, this is your track bar. Look at the passenger side connection point of the track bar from directly underneath while your friend turns your steering wheel back and forth. The steering wheel should be moved back and forth just under a quarter turn each way. When you are watching the connection, the trackbar should stay firmly in place, if it looks like one is moving without the other then you have a bad track bar bushing. If your track bar was moving around but your bolt was staying firmly in place, then your bushing is worn out and should be replaced.

Tie-rod ends: Checking your tie-rod ends is quite simple and can be done in just a couple minutes. To check your tie rod ends start by using a jack to lift one of your front wheels off the ground, next have your friend that was helping you check your track bar watch the tie rod end for that wheel. Place your hands on the left and right side of the wheel and try to wiggle it from side to side, if your friend sees the tie-rod wiggle back and forth and the tie-rod itself isn’t moving the tie-rod is worn out. If the tie-rod is worn out or if the rubber boot on the tie-rod is ripped open or missing then the tie-rod should be replaced. Repeat this test on the other wheel to check the other tie-rod end.

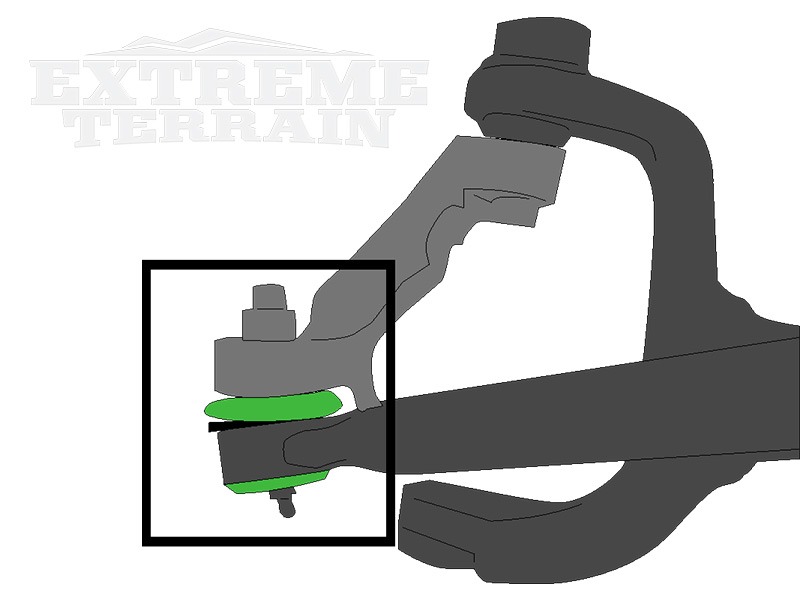

Ball joints: The Ball Joints are the second most common part to cause Death Wobble, if they are worn out or damaged. These important joints are covered with a soft rubber boot and are filled with lubricating grease. The joint is designed to articulate and provide soft and controlled steering. If the protective boot has ruptured or the grease has leaked out, the joint could be compromised, causing dangerously excessive movement vertically or side-to-side. A quick visual inspection could provide an immediate assessment of the joint’s condition.

Another test can be done by using a jack to lift one of your wheels of the ground and have your friend watch your ball joints closely one at a time. Take a pry bar and place it between the floor and your tire, using the pry bar push up on the tire a couple times. If your friend sees any slight movement between your ball joint and the steering knuckle then it is worn out and should be replaced. Have your friend watch the other ball joint for that wheel and do the test again to see if the second is worn out. After you finish testing that side, move to the other side and repeat the tests.

Control arms: You can perform a quick visual inspection of the upper and lower control arms to see if they are bent or have any cracks in them. You should also check the control arm bushings looking for gouged or missing rubber.

Wheel bearings: The wheel bearings on your Wrangler are tested in a manner much like your tie-rod ends and are very easy to test. Begin by using a jack to lift one of your front wheels off the ground and place your hands on the top and bottom of the wheel. Try to wiggle the wheel from the top and bottom, if you feel movement, your wheel bearing is most likely worn out and should be replaced. Move to the other side and repeat this test.

After any of your steering components are replaced it is a good idea to bring your Wrangler in for a front wheel alignment.

Can I Fix It at Home?

An inexpensive and easy preventive solution is the replacement of the factory bolts to a higher grade alternative. Bolt kits from Synergy for example provide high grade alternatives to the factory hardware and allow you to tighten the components at a higher rate.

In addition, if you plan on upgrading your Jeep’s suspension, it’s critical to loosen the bolts for the front & rear track bars and all control arms, followed by shaking the Jeep. This allows important suspension components to settle properly and prevent mounting points to bind. Once settled all bolts should be properly tightened to the torque recommendations. Marking, the bolt and mounting point with a line using a white marker, provides a quick visual indicator if the bolt has moved/loosened. It’s also recommended to have your Jeep properly aligned by a professional after any steering/suspension modification and as part of your routine maintenance.

Finally, it’s also good practice to inspect all these mounting points and all joints/rubber protective boots for excessive wear or damage. Immediately replacing or addressing issues early on will help prevent any future problems.

What is Death Wobble?

Death wobble is a rapid oscillation from side to side in your steering components and results in your steering wheel moving very quickly from side to side. It has earned this name because it feels like your Wrangler is literally falling apart and that letting go of the steering wheel can lead to a very bad day. When this occurs it becomes extremely difficult to control your Wrangler and the only way to get it to stop is to slow down, sometimes it is necessary to come to a complete stop. Death wobble typically occurs at speeds above 45 mph and in most cases requires a trigger like hitting a bump or a pothole, but can also happen at speeds under 45 mph. One of the common myths about death wobble is that it doesn’t happen to stock Jeeps, only ones that have been lifted. This is not true, it is actually possible to have death wobble in ANY vehicle with a solid front axle, and however it is true that if you have recently done any suspension upgrades (Ex: Lift kits) you may be more likely to experience death wobble.

Unlike normal shimming or vibrations from unbalanced wheels, death wobble is a distinctly harsher oscillating force and is very difficult to control. If you’re faced with this unfortunate situation, here are some steps to look into and possible help solve the problem.

What Causes Wrangler to Death Wobble?

Death wobble is caused by loose or damaged steering components, however it can also be caused by incorrectly installing steering or suspension components. The first thing you should check is to make sure that nothing is bent or broken, look at all of your front suspension components and if you see anything that is damaged it is a good idea to replace it. Your front track bar, drag link, steering knuckles, ball joints, steering stabilizer, upper and lower control arms, and even bushings should be checked for damage or excessive wear. In addition to properly checking that all corresponding hardware is properly tighten to the correct torque specifications. Another important thing to check is your wheels, tires and alignment. While unbalanced tires and wheels being out of alignment won’t cause death wobble, it can help trigger or even amplify it, so it’s a good thing to check just in case.

What to do When Death Wobble Happens?

If you are driving along and death wobble happens, the safest thing to do is pull over. Don’t let go of the steering wheel but maintain a lightly grip, the sudden harsh steering wheel movements can cause damage to your fingers if you have a tight misplaced grip, try to stay in the lane while slowing down and don’t pull over until the wobble stops, in most situations if you slow down enough the wobble will stop, but other times coming to a complete stop is necessary. If you try to pull over while you are wobbling at a high speed it can be very dangerous and you could lose control, just try to slow down quickly and safely without aggressive braking or forceful/quick movements of the steering wheel.

How to Fix Wrangler Death Wobble?

One thing that many people do is simply install a new steering stabilizer, however this does not fix death wobble. Steering stabilizers in some situations can temporarily get rid of death wobble, therefore masking the serious problem. During the diagnosing of the issue, it sometimes help disconnecting the stabilizer in order to properly pin-point the problem. The best thing to do is inspect your steering components and find the part or parts that are damaged or worn out, most likely it will be the front track bar, tie-rod ends or the ball joints.

How do I Figure Out What Needs Fixed?

Track bar: The front Track Bar is designed to absorb a tremendous amount of force, as a result the two anchoring points are extremely critical and should be the first stop in your investigation of the problem.

The “Frame Mount” bolt is especially known to be problematic. This high grade bolt requires 125 ft./lbs. of tightening torque. If loose, the bar’s force could oblong/enlarge the frame mount’s hole, causing the bar to have excessive play.

Another way to see if your track bar is worn out and needs replacement is to grab a buddy and check it out. Have your friend hop into the jeep and start it up, then have them put it in neutral with the parking brake on or if you drive an automatic, put it in park. Next lay down and look underneath your wrangler at the front axle, you should see a bar that connects the passenger side of your axle to the driver’s side of the frame and it will have a curve to part of it, this is your track bar. Look at the passenger side connection point of the track bar from directly underneath while your friend turns your steering wheel back and forth. The steering wheel should be moved back and forth just under a quarter turn each way. When you are watching the connection, the trackbar should stay firmly in place, if it looks like one is moving without the other then you have a bad track bar bushing. If your track bar was moving around but your bolt was staying firmly in place, then your bushing is worn out and should be replaced.

Tie-rod ends: Checking your tie-rod ends is quite simple and can be done in just a couple minutes. To check your tie rod ends start by using a jack to lift one of your front wheels off the ground, next have your friend that was helping you check your track bar watch the tie rod end for that wheel. Place your hands on the left and right side of the wheel and try to wiggle it from side to side, if your friend sees the tie-rod wiggle back and forth and the tie-rod itself isn’t moving the tie-rod is worn out. If the tie-rod is worn out or if the rubber boot on the tie-rod is ripped open or missing then the tie-rod should be replaced. Repeat this test on the other wheel to check the other tie-rod end.

Ball joints: The Ball Joints are the second most common part to cause Death Wobble, if they are worn out or damaged. These important joints are covered with a soft rubber boot and are filled with lubricating grease. The joint is designed to articulate and provide soft and controlled steering. If the protective boot has ruptured or the grease has leaked out, the joint could be compromised, causing dangerously excessive movement vertically or side-to-side. A quick visual inspection could provide an immediate assessment of the joint’s condition.

Another test can be done by using a jack to lift one of your wheels of the ground and have your friend watch your ball joints closely one at a time. Take a pry bar and place it between the floor and your tire, using the pry bar push up on the tire a couple times. If your friend sees any slight movement between your ball joint and the steering knuckle then it is worn out and should be replaced. Have your friend watch the other ball joint for that wheel and do the test again to see if the second is worn out. After you finish testing that side, move to the other side and repeat the tests.

Control arms: You can perform a quick visual inspection of the upper and lower control arms to see if they are bent or have any cracks in them. You should also check the control arm bushings looking for gouged or missing rubber.

Wheel bearings: The wheel bearings on your Wrangler are tested in a manner much like your tie-rod ends and are very easy to test. Begin by using a jack to lift one of your front wheels off the ground and place your hands on the top and bottom of the wheel. Try to wiggle the wheel from the top and bottom, if you feel movement, your wheel bearing is most likely worn out and should be replaced. Move to the other side and repeat this test.

After any of your steering components are replaced it is a good idea to bring your Wrangler in for a front wheel alignment.

Can I Fix It at Home?

An inexpensive and easy preventive solution is the replacement of the factory bolts to a higher grade alternative. Bolt kits from Synergy for example provide high grade alternatives to the factory hardware and allow you to tighten the components at a higher rate.

In addition, if you plan on upgrading your Jeep’s suspension, it’s critical to loosen the bolts for the front & rear track bars and all control arms, followed by shaking the Jeep. This allows important suspension components to settle properly and prevent mounting points to bind. Once settled all bolts should be properly tightened to the torque recommendations. Marking, the bolt and mounting point with a line using a white marker, provides a quick visual indicator if the bolt has moved/loosened. It’s also recommended to have your Jeep properly aligned by a professional after any steering/suspension modification and as part of your routine maintenance.

Finally, it’s also good practice to inspect all these mounting points and all joints/rubber protective boots for excessive wear or damage. Immediately replacing or addressing issues early on will help prevent any future problems.